Manager Jim Grocock knows when most people look at the piles of rubble in and around Glen Hunter & Associates (GH&A), they don’t see what he sees.

“When people come in here, they see a bunch of junk,” Grocock said. “Really, it’s bags of money.”

The piles of bricks and mix are the remnants of refractory brick from former large-scale furnaces. The Noble REMC member resells the costly, raw materials as-is or creates a mix that can be used as a calming powder for the creation of steel, at places such as Steel Dynamics, Inc. It can crush hundreds of tons of materials a day.

A lucrative, international business not many are willing to undertake, the company finds a way for every part of the brick to be “beneficially reused.” One glass float furnace can result in about 1,500 tons of refractory materials. GH&A can then create five to six products for purchase within the industry.

So how tough can crushing or cleaning bricks really be?

“These bricks literally laugh at steel,” Grocock said. This results in a lot of maintenance costs for the machines and equipment they use on a daily basis. “It’s labor-intensive, dirty work.”

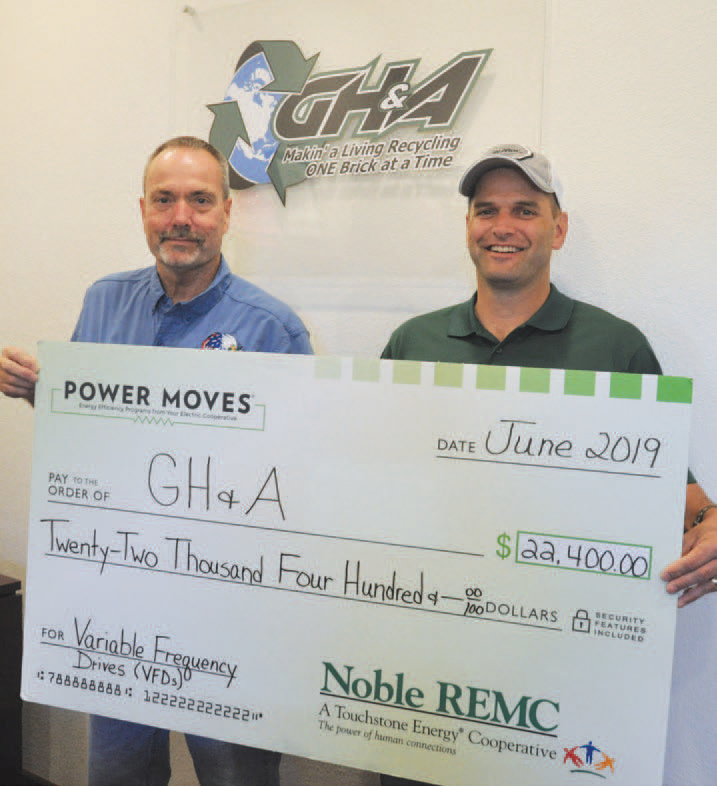

That’s why every penny counts, and GH&A knows to turn to Noble REMC and our POWER MOVES® program for energy efficiency rebates for upgrades at the site.

Most recently, the Kendallville site installed variable-frequency drives in seven electric motors to make its brick crushing system more efficient, earning it $22,400 in an upfront check and saving more money over the life of the drive.

POWER MOVES offers $80 per horsepower of the VFD, and with one motor sporting 200 horsepower, the cash back quickly added up.

“We put up millions of dollars for the machines, but it’s nice to know you get a kickback for making this decision,” Grocock said of choosing energy-efficient options. “Who else gives you money back?”

And it doesn’t just help the business, it helps the cooperative and our members keep costs lower by not putting more pressure on the distribution system while they work.

“The installation of VFDs helps with our demand, because they’re not allowing all of their machines to be on at the same time,” Noble REMC Energy Advisor Brian Hawk said.

The business first began in Delta, Ohio, nearly 30 years ago, working mainly in the glass industry. It opened its Kendallville location about seven years ago and expanded into the steel industry, situated between multiple steel manufacturers.

As the business has become the go-to for such work, which is regulated by the Environmental Protection Agency, it continues to expand, and in the future, Grocock hopes to engage the nearby rail system to his benefit in shipping the heavy materials to nearby partners.

And when these changes and expansions happen, Noble REMC will be there to help the business develop and use its energy to its greatest potential.